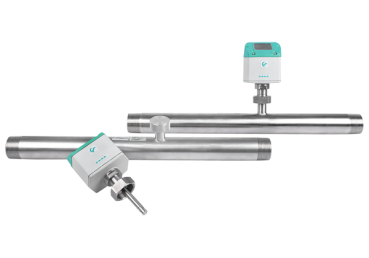

Product information "Inline Flow meter VA 520 - thread"

Inline Flow meter VA 520 - thread

When it comes to an inline flow meter like the VA 520 with a thread connection, the thread type and size can have an impact on the air quality in a compressed air system. The thread connection of the flow meter can potentially introduce contaminants into the system if not properly sealed or if the thread material is not compatible with the air quality requirements.

It is important to ensure that the thread connection of the flow meter is properly sealed and does not introduce contaminants into the system. Additionally, the material of the thread should be compatible with the air quality requirements to prevent any contamination issues.

When selecting an inline flow meter like the VA 520 for a compressed air system, it is essential to consider the thread connection type, size, and material to ensure that it does not negatively impact the air quality according to the ISO 8573 standard. It is recommended to consult the manufacturer's specifications and guidelines to ensure that the flow meter meets the air quality requirements of the system.

Available items Inline Flow meter VA 520 - thread measuring section:

| Product | Description | Order No. |

| VA 520 flow meter with 1/2" measuring section | 0695 1521 | |

| VA 520 flow meter with 3/4" measuring section | 0695 1522 | |

| VA 520 flow meter with 1" measuring section | 0695 1523 | |

| VA 520 flow meter with 1 1/2" measuring section | 0695 1524 | |

| VA 520 flow meter with 2" measuring section | 0695 1525 |

| 1/2" | 3/4" | 1" | 1 1/2" | 2 | ||

| l/min (cfm) | l/min (cfm) | l/min (cfm) | l/min (cfm) | l/min (cfm) | ||

| Reference conditions DIN 1945 / ISO 1217: 20 °C, 1000 mbar | ||||||

| Air | Low-Speed (50 m/s) | 20 (14) | 45 (25) | 75 (45) |

195 (115) | 320 (190) |

| Standard (92,7 m/s) | 45 (25) | 85 (50) | 145 (85) |

365 (215) | 600 (350) | |

| Max (185 m/s) | 90 (50) | 175 (100) | 290 (170) | 730 (430) | 1195 (700) | |

| High -Speed (224 m/s) | 110 (60) | 215 (125) | 355 (210) | 885 (520) | 1450 (850) | |

| Setting to DIN 1343: 0 °C, 1013.25 mbar | ||||||

| Nitrogen (N2) | Low-Speed (50 m/s) | 20 (13) | 40 (25) | 70 (40) |

180 (105) | 295 (175) |

| Standard (92,7 m/s) | 40 (20) | 80 (45) | 135 (75) |

335 (195) | 550 (320) | |

| Max (185 m/s) | 80 (45) | 160 (95) | 270 (155) | 670 (395) | 1100 (645) | |

| High-Speed (224 m/s) | 100 (55) | 195 (115) | 325 (190) | 815 (475) | 1330 (780) | |

| Setting to DIN 1343: 0 °C, 1013.25 mbar | ||||||

| Oxygen (O2) | Low-Speed (50 m/s) | 20 (13) | 45 (25) | 75 (40) |

185 (115) | 305 (180) |

| Standard (92,7 m/s) | 40 (25) | 80 (45) | 140 (80) |

345 (205) | 570 (335) | |

| Max (185 m/s) | 85 (50) | 165 (95) | 280 (165) | 695 (410) | 1140 (670) | |

| High-Speed (224 m/s) | 105 (60) | 205 (120) | 340 (200) | 845 (495) | 1380 (810) | |

Advantages of the VA 520 flow meter:

- Measurement of mass flow rate, output of standard volume flow rate

- High accuracy for both small and large flows

- Pressure and temperature compensated by the thermal mass flow principle

- Easy installation and removal of the sensor, the integrated measuring section can remain in the line for cleaning or recalibration of the sensor and can simply be closed with a sealing cap

- No moving parts, therefore low maintenance

- Vanishingly low pressure loss due to vanishingly low blockage of the diameter

- Can be used for compressed air and non-corrosive gases such as nitrogen, oxygen, argon, helium, etc.

Technical Data VA 520

| Parameters | m3/h, l/min (1000 mbar, 20 °C) in case of compressed air or Nm3/h, Nl/min (1013 mbar, 0 °C) in case of gases |

| Units adjustable via keys at display | m3/h, m3/min, l/min, l/s, ft/min, cfm, m/s, kg/h, kg/min, g/s, lb/min, lb/h |

| Sensor | Thermal mass flow sensor |

| Measured medium | Air, gases |

| Gas types are adjustable over CS service software or CS data logger | Air, nitrogen, argon, CO2, oxygen |

| Measuring range | See Measuring range table |

| Accuracy (m.v: of meas. value) (f.s.: of full scale) | ±1.5% of m.v. ± 0.3% of f.s. on request: ±1% of m.v. ± 0.3% of f.s. |

| Operating temperature | -30... 80°C |

| Operating pressure | -1...16 bar optionally up to PN 40 |

| Digital output | RS 485 interface, (Modbus-RTU), optional: Ethernet interface PoE, M-Bus |

| Analogue output | 4...20 mA for m3/h or l/min |

| Pluse output | 1 pulse per m3 or per litre electrically isolated. Pluse weight can be set on the display. Alternatively, the pluse output can be used as an alarm relay |

| Supply | 18...36 VDC, 5 W |

| Burden | < 500 Ω |

| Housing | Polycarbonate (IP 65) |

| Measuring section | Stainless steel, 1.4301 or 1.4571 |

| Process connection | R 1/4" to R 2" (BSP British Standard Piping) or 1/2" to 2" NPT thread |

| Mounting position | any |

| Flow measuring ranges VA 520 (max version 185 m/s) for compressed air (ISO 1217: 1000 mbar, 20°C) | |||||||||

| Connection thread | Outer pipe | Inner pipe | L | L1 | H | H1 | A | ||

| mm | mm | mm | mm | mm | mm | mm | |||

| R 1/2" | 21.3 | 16.1 | 300 | 210 | 176.4 | 165.7 | 20 | ||

| R 3/4" | 26.9 | 21.7 | 475 | 275 | 179.2 | 165.7 | 20 | ||

| R 1" | 33.7 | 27.3 | 475* | 275 | 182.6 | 165.7 | 25 | ||

| R 1 1/2" | 48.3 | 41.9 | 475* | 275 | 186.9 | 165.7 | 25 | ||

| R 2" | 60.3 | 53.1 | 475* | 275 | 195.9 | 165.7 | 30 | ||

| * Attention: shortened inlet section. Please observe the recommended minimum inlet section (length = 15 x inner diameter) on site! | |||||||||

How inline flow meter VA 520 - thread can effect on ISO air quality chart?

The ISO air quality chart provides guidelines for the maximum allowable levels of contaminants in compressed air systems based on the ISO 8573 standard. The ISO 8573 standard specifies purity classes for different contaminants such as particles, water, and oil in compressed air systems.When it comes to an inline flow meter like the VA 520 with a thread connection, the thread type and size can have an impact on the air quality in a compressed air system. The thread connection of the flow meter can potentially introduce contaminants into the system if not properly sealed or if the thread material is not compatible with the air quality requirements.

It is important to ensure that the thread connection of the flow meter is properly sealed and does not introduce contaminants into the system. Additionally, the material of the thread should be compatible with the air quality requirements to prevent any contamination issues.

When selecting an inline flow meter like the VA 520 for a compressed air system, it is essential to consider the thread connection type, size, and material to ensure that it does not negatively impact the air quality according to the ISO 8573 standard. It is recommended to consult the manufacturer's specifications and guidelines to ensure that the flow meter meets the air quality requirements of the system.

Login