COMPRESSED AIR TREATMENT

Maximize efficiency with compressed air treatment solutions

Welcome to BERG KOMPRESSOREN GmbH, where we specialize in optimizing industrial processes through advanced compressed air treatment solutions. In this guide, we explore the importance of compressed air treatment and how our cutting-edge technologies, products and solutions can improve the efficiency and reliability of your operations.

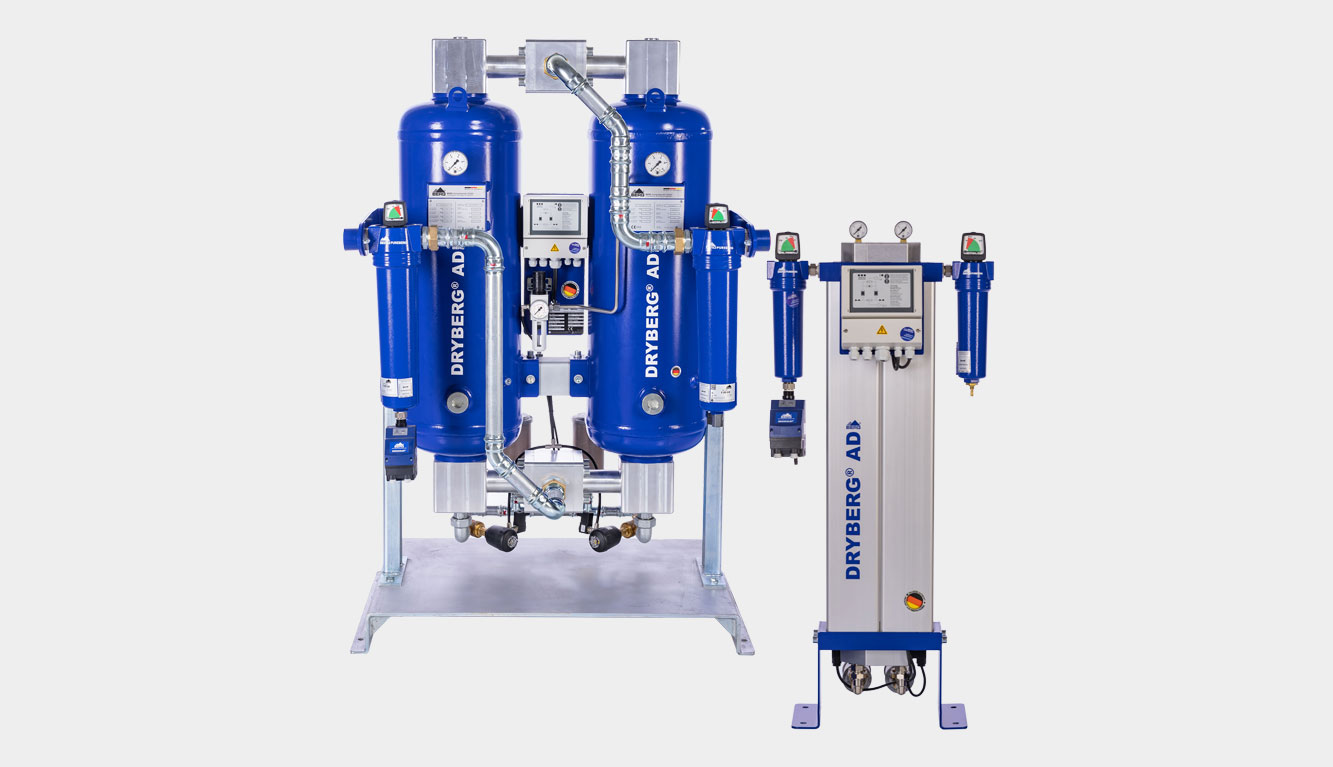

DRYBERG®, Compressed Air Dryer with high energy efficiency

The optimum compressed air and gas treatment solution can only be achieved by the application of a complete treatment solution. BERG offers an extensive range of Dryer solutions which, by working together in perfect harmony, ensure that your compressed air will be perfectly free of condensate.

PURBERG®, Highly efficient and reliable compressed air filtration

BERG filter housings were developed for the highly efficient removal of solid particles, condensate water, oil aerosols, hydrocarbons, odors from compressed air systems. To achieve the required compressed air quality according to ISO 8573-1, a suitable filter element (G, F, S, A) must be installed in the filter housing. BERG filter technology guarantees low operating costs, long service life, excellent process reliability, and reliable filtration.

How do I choose an air dryer?

To choose the right air dryer, you need to know the maximum flow rate, pressure and inlet air temperature. In addition, you should have enough information about the ambient air temperature, dew point of the desired pressure and installation requirements such as suitable space and water and electricity required.

- Identify Your Air Quality Requirements according to ISO8573-1

- Assess the environmental conditions in which the compressed air will operate

- Determine the Flow Rate and Pressure of your compressed air system

- Understand the Types of Compressed Air Dryers DRYBERG RF, AD, AD-CT, ADP

- Energy consumption is a significant consideration in selecting a compressed air dryer

- Evaluate Maintenance Requirements as different dryers have varying maintenance needs

- Assess your budget and evaluate the total cost of ownership

- Ask for Expert Advice, If you're unsure which type of compressed air dryer is best for your specific application, consider our consulting and ask BERG as most expert of compressed air system supplier.

What are the types of air dryers?

The two main types of compressed air dryers in industry and medical applications are:• Refrigerated dryers - DRYBERG® RF/AC

• Desiccant or adsorption dryers - DRYBERG®️ AD / AD-CT / ADP

What is ISO 8573 1?

ISO 8573-1 is an international standard that specifies the purity classes of compressed air. It provides guidelines for measuring and categorizing the quality of compressed air based on the presence of various contaminants, including particles, water, and oil. ISO 8573-1 focuses on the measurement and classification of particulate contamination in compressed air. It defines the maximum allowable concentration of solid particles of various sizes within the compressed air. Particles: This part of the code represents the concentration of solid particles in the compressed air. It is typically expressed as the number of particles per cubic meter at specified particle size ranges, such as 0.1 µm, 0.5 µm, and 5 µm. Water: ISO 8573-1 also addresses water content in compressed air, which can result from condensation. Water content is represented by a separate part of the code. Oil: The presence of oil or oil vapor in the compressed air is covered in the third part of the code.

The ISO 8573-1 standard is widely used in various industries and applications where the quality of compressed air is critical, such as in pharmaceuticals, food and beverage production, electronics manufacturing, and many others. It helps ensure that the compressed air used in these processes meets the required quality standards and does not adversely affect the products or equipment it comes into contact with. Different applications may have specific requirements for compressed air quality.

The ISO 8573-1 standard is widely used in various industries and applications where the quality of compressed air is critical, such as in pharmaceuticals, food and beverage production, electronics manufacturing, and many others. It helps ensure that the compressed air used in these processes meets the required quality standards and does not adversely affect the products or equipment it comes into contact with. Different applications may have specific requirements for compressed air quality.

| G General Filter |

F Fine Filter |

S Superfine Filter |

A Activated carbon |

|

| Quality class - particle (ISO8573-1) | 3 | 2 | 1 | 1 |

| Residual oil content (mg/m3) | <1 | <0.1 | <0.01 | <0.005 |

| Quality class - Oil (ISO8573-1) | 3 | 2 | 1 | 0 |

| Pressure drop - new element (mbar) | 20 | 50 | 60 | 60 |

| change filter cartridge at pressure drop (mbar) | 350 | 350 | 350 | 6 months |

| Filter media | Acrylic fibers | Borosilicate microfibers | Activate carbon | |