The clean solution that fits your budget and protects the environment: Condensate processing with OWAMAT ®

Legislators demand that discharged condensate is processed safely and properly. BEKO make it easy for operators to meet the legal requirements – with our extensive range of condensate processing solutions that reflect our commitment to sustainability. With our Oil water separator OWAMAT ® oil water separator reaction splitting plants, we offer cost-effective and environmentally friendly solutions for the disposal of dispersed and emulsified condensates. These systems are designed to be environmentally friendly. They are cost-efficient on-site units for the processing of condensate in compliance with all applicable statutory regulations.Function of OWAMAT®

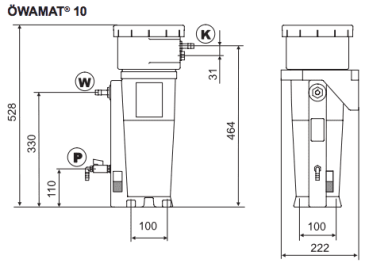

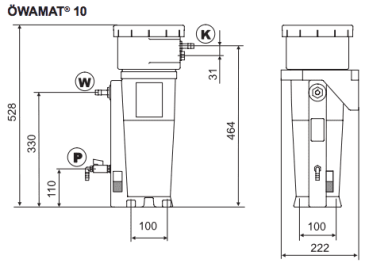

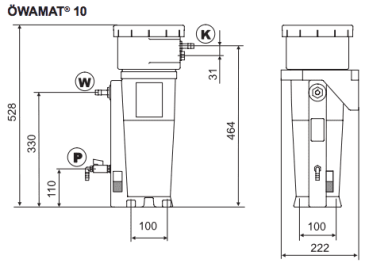

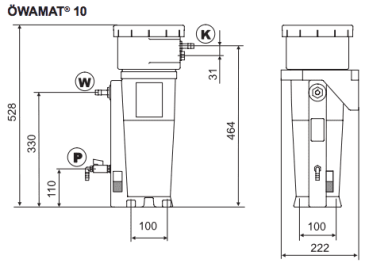

For the processing, the oil-containing condensate first flows under pressure into the pressure relief chamber. Here, the pressure is reduced without causing turbulence in the downstream separating tank for the separation of free oils. Any entrained coarse dirt particles are retained in a removable receiver. In the separating tank, the oil settles on the surface as a result of gravity separation and is led into the spillproof oil receiver.Technical Data of Oil water separator OWAMAT® 10

| Oil water separator OWAMAT | OWAMAT® 10 |

| max. compressor performance: | 2.4 m3/min |

| Container volume: | 10 l |

| Capacity: | 4.3 l |

| Pre lter: | 2.5 l |

| Main lter: | 2.6 l |

| Condensate inlet (hose size): | 2 x G1⁄2 inside (Ø inside = 10 mm) |

| Water (hose size): | 1 x G1⁄2 inside (Ø inside = 10 mm) |

| Weight (empty): | 3.5 kg |

| Min./max. temperature | +5 ... +60 °C |

| Max. operating pressure at inlet | 16 bar |

Maintenance of ÖWAMAT®

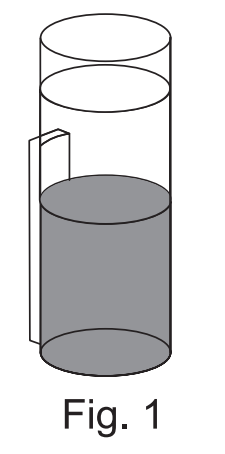

| Weekly wastewater test | – Fill the test glass at the Sampling cock.

– Compare the cloudiness with the reference jar |

| If the sample is clearer than the

reference cloudiness

– the filter is O.K. (Fig. 1) |

|

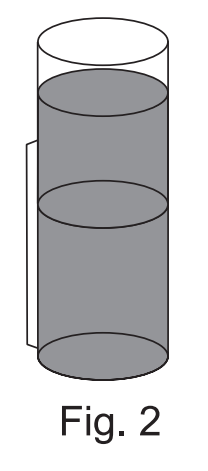

| If the sample is cloudier than the

reference cloudiness

– the filter needs to be changed! (Fig. 2) |

|

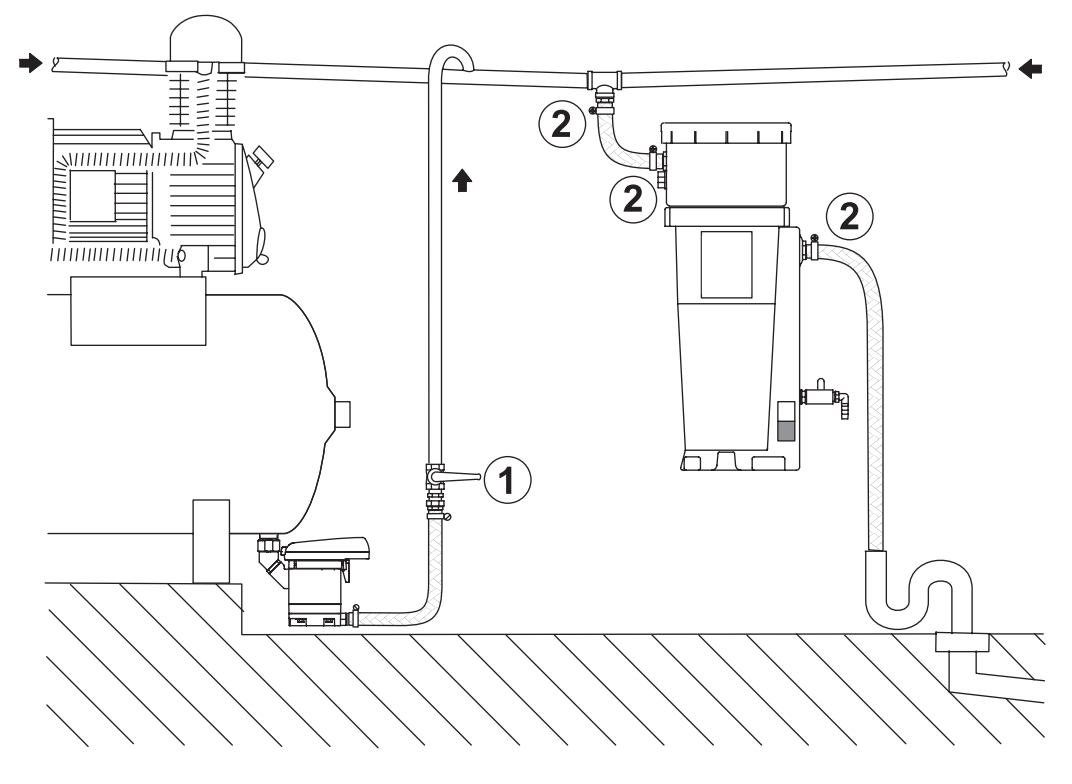

| Before any maintenance – Shut off condensate inlet (1) if necessary switch off compressor |

Maintenance – Hoses and hose connections must be inspected regularly (2) |

Downloads

Technical Data of Oil water separator OWAMAT® 10 , PDF( Size: 747 KB )

Catalog Oil water separator , PDF( Size: 309 KB )

0 of 0 reviews

Login

Accesories

All articles in this group