Product information "METPOINT®️ OCV complete"

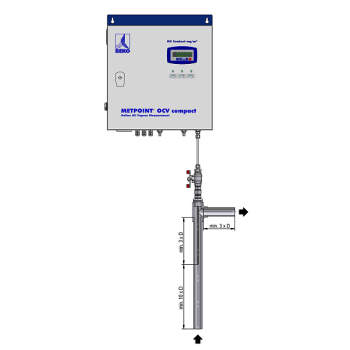

METPOINT®️ OCV compact

- Reproducible accuracy of the measurement values by utilising reference gas generation

- Automatic monitoring for the reference gas and sensor electronics

- Issuing and transferring of alarm signal messages

Reliable

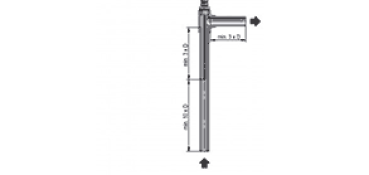

- Pressure range from 3 … 16 bar

- Online-monitoring for the oil vapour concentration

- Data transfer to display as standard feature and control centre with customary communication methods

User-friendly

- Unambiguous visualisation of all measurement values

- Flexible installation

- Robust industrial housing

Continuous oil vapour measuring for your process safety

Oil contamination can affect compressed air processing systems in many different ways, posing a danger to the safety of workers, the environment and the production equipment. Monitoring systems such as the METPOINT OCV compact continuously control the compressed air accurately and according to applicable standards for the residual oil vapour concentration . You therefore retain the compressed air quality.

Tiny oil particles are an often underestimated risk in the processing of compressed air. Such particles occur in many places in the compressed air system in the form of oil vapour or aerosols and can lead to serious quality problems. The consequences are not only increased scrap or time-consuming rework: even the finest of oil vapour components can contaminate the final product or whole production plants.

Simple and safe operation

The METPOINT OCV compact provides information about the current measurement value (oil vapour in mg/m³), the ISO 8573 oil class as well as the status of the measuring system and its components. In addition, the status of the measuring cell and the reference gas generation (purificator) will be displayed visually. You therefore always have an overview about the measurement values, oil class, system status at all times and know immediately that your compressed air is correct.

Advantages of the METPOINT OCV compact system

Safe- Reproducible accuracy of the measurement values by utilising reference gas generation

- Automatic monitoring for the reference gas and sensor electronics

- Issuing and transferring of alarm signal messages

Reliable

- Pressure range from 3 … 16 bar

- Online-monitoring for the oil vapour concentration

- Data transfer to display as standard feature and control centre with customary communication methods

User-friendly

- Unambiguous visualisation of all measurement values

- Flexible installation

- Robust industrial housing

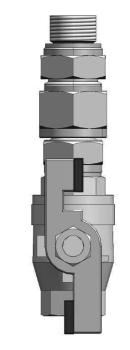

METPOINT®️ OCV compact with complete accessories, standard measuring section DN50, 16bar

Downloads

Technical information of METPOINT®️ OCV compact, PDF( Size: 800 KB )

Technical Data of METPOINT®️ OCV compact, PDF( Size: 133 KB )

Catalog METPOINT®️ OCV compact , PDF( Size: 1.7 MB )

Login