Product information "METPOINT®️ OCV compact"

METPOINT®️ OCV compact - oil vapour measuring instrument

Integrated reference gas generation

The METPOINT OCV compact has been developed for measuring hydrocarbon vapours and gases in compressed air system applications. The detection levels are as low as one thousandth mg/m³ of residual oil vapour content and are executed continuously in ongoing operation. Shortened measuring intervals enable the rapid and reliable display of even the smallest deviations. This on-line monitoring process provides the certainty about the quality of your compressed air as an important element of your process safety at all times and at all quality-critical system points. The measurement data can be utilised for documenting the compressed air quality and for identifying contamination sources.

Function of oil vapour measuring

In the METPOINT®️ OCV compact system, a PID sensor works according to the principle of photo-ionization using a UV lamp. To increase the precision and to compensate for the smallest fluctuations, the determined values are temperature and pressure compensated. This fulfills the requirements of ISO 8573. As a continuous self-control of the measuring system, a reference gas generated by means of an integrated catalytic converter is used. In the periodic change between measuring air and reference air, the function of the PID measuring cell is continuously controlled and adjusted.

Internal reference gas generation by means of a purifierIntegrated reference gas generation

The METPOINT OCV compact has integrated reference gas treatment by means of a patented catalytic converter. The compressed air is hereby passed on to a heated catalytic converter surface and the hydrocarbons are decomposed catalytically to water (H₂O) and carbon dioxide (CO₂). This reference gas is then continuously routed in alternation with the normal compressed air sample into the measuring chamber and the oil content is measured with the photo-ionisation detector (PID). The measuring chamber is both regularly “cleaned” by this reference gas generation and the measuring system is inspected for its zero point. This “self-monitoring” provides you with the assurance that the system is working accurately in the long term.

Technical Data METPOINT®️ OCV compact

| METPOINT | METPOINT OCV compact |

| Medium | Compressed air free of aggressive, corrosive, caustic, toxic, flammable and combustion supporting materials or substances. The use of a compressed air preparation adapted to the measurement task is necessary. |

| Measured value | Residual oil content in mg of oil/normal m³, relative to 1.0 bar, +20°C, 0% relative humidity, according to ISO 8573-1 |

| Detectable substances | Poly-alpha-olefines, aromatic and aliphatic hydrocarbons, functional hydrocarbons Compressed air free of aggressive, corrosive, caustic, toxic, flammable and oxidizing substances |

| Applications | Downstream of activated carbon filter and activated-carbon adsorber, downstream of BEKOKAT® (catalytic converter), downstream of oil-free compressing compressor, each with pre-switched filtration and drying |

| Ambient temperature, minimum/maximum | +5°C ... +45°C, rel. humidity ≤ 75%, non-condensing |

| Storage temperature | +5 °C ... +50 °C |

| Ambient pressure | 800 ... 1200 mbar [a] |

| Climatic resistance | max. +10 °Ctd |

| Compressed air temperature, minimum/maximum | +5 °C ... +50 °C |

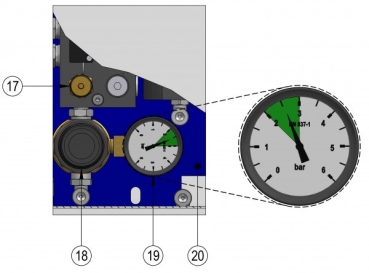

| Operating pressure | 3 … 16 bar(g), optional pressure reducer which can be pre-switched for up to 300 bar(g) |

| Settings for operating pressure | By means of integrated pressure reducer with display |

| Measuring gas humidity | ≤ 40 % relative humidity, max. pressure dew point +10 °C, non-condensing humidity |

| Compressed air connection | G 1/8” internal thread according to ISO 228-1 |

| Measurement values | mg/standard m³, pressure and temperature compensated |

| Measuring range | ≤ 0,01 … 2,50 mg/m³ |

| Measured value display | a new measured value every 4 seconds |

| Calibrated measuring range | ≤ 0.01 … 1.25 mg/m³ residual oil content, according to ISO 8573-1 |

| Detection limit (residual oil) | 0,001 mg/m³ |

| Measuring range and accuracy | ≤ 0,01 … 0,5 mg/m³ ± 0,003 ≥ 0,5 … 1,0 mg/m³ ± 0,10 ≥ 1,0 … 2,5 mg/m³ ± 0,10 |

| Measuring gas flow rate | approx. 1.20 standard litres / minute relative to 1.0 bar(a) and +20 °C, in depressurised state |

| Display for adhering to an ISO residual oil vapour class |

As LED (red/green) |

| Reference gas generation | Integrated catalytic converter |

| Voltage supply | 100 ... 240 VAC / 1 Ph. / PE / 50 ... 60 Hz / ± 10 % |

| Degree of protection | IP54 / DIN EN 60529 |

| Interfaces | 4 … 20 mA analogue output, 2-conductor system, RS-485, MODBUS RTU for the transmission of measured values 1 alarm contact, normally open contact |

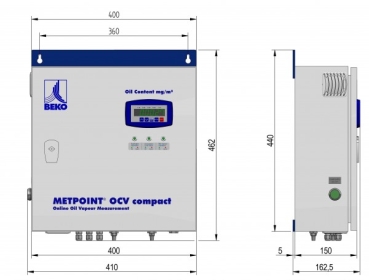

| Dimensions | 410 x 440 x 163 mm (W x H x D) |

| Weight | approx. 16.3 kg |

Downloads

Technical information of METPOINT®️ OCV compact, PDF( Size: 800 KB )

Technical Data of METPOINT®️ OCV compact, PDF( Size: 133 KB )

Catalog METPOINT®️ OCV compact , PDF( Size: 1.7 MB )

Login