Oil Content Meter

Continuous oil vapour measuring for your process safety

Oil contamination can affect compressed air processing systems in many different ways, posing a danger to the safety of workers, the environment and the production equipment. Monitoring systems such as the METPOINT OCV compact continuously control the compressed air accurately and according to applicable standards for the residual oil vapour concentration . You therefore retain the compressed air quality.

METPOINT®️ OCV complete

Net €9,241.00

€10,996.79*

METPOINT®️ OCV compact

Continuous oil vapour measuring for your process safety

Oil contamination can affect compressed air processing systems in many different ways, posing a danger to the safety of workers, the environment and the production equipment. Monitoring systems such as the METPOINT OCV compact continuously control the compressed air accurately and according to applicable standards for the residual oil vapour concentration . You therefore retain the compressed air quality.

Tiny oil particles are an often underestimated risk in the processing of compressed air. Such particles occur in many places in the compressed air system in the form of oil vapour or aerosols and can lead to serious quality problems. The consequences are not only increased scrap or time-consuming rework: even the finest of oil vapour components can contaminate the final product or whole production plants.

Simple and safe operation

The METPOINT OCV compact provides information about the current measurement value (oil vapour in mg/m³), the ISO 8573 oil class as well as the status of the measuring system and its components. In addition, the status of the measuring cell and the reference gas generation (purificator) will be displayed visually. You therefore always have an overview about the measurement values, oil class, system status at all times and know immediately that your compressed air is correct.

Advantages of the METPOINT OCV compact system

Safe

- Reproducible accuracy of the measurement values by utilising reference gas generation

- Automatic monitoring for the reference gas and sensor electronics

- Issuing and transferring of alarm signal messages

Reliable

- Pressure range from 3 … 16 bar

- Online-monitoring for the oil vapour concentration

- Data transfer to display as standard feature and control centre with customary communication methods

User-friendly

- Unambiguous visualisation of all measurement values

- Flexible installation

- Robust industrial housing METPOINT®️ OCV compact with complete accessories, standard measuring section DN50, 16bar

Downloads

Technical information of METPOINT®️ OCV compact, PDF( Size: 800 KB )

Technical Data of METPOINT®️ OCV compact, PDF( Size: 133 KB )

Catalog METPOINT®️ OCV compact , PDF( Size: 1.7 MB )

METPOINT®️ OCV compact

Net €7,786.00

€9,265.34*

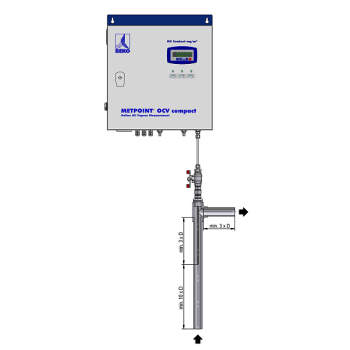

METPOINT®️ OCV compact - oil vapour measuring instrument

The METPOINT OCV compact has been developed for measuring hydrocarbon vapours and gases in compressed air system applications. The detection levels are as low as one thousandth mg/m³ of residual oil vapour content and are executed continuously in ongoing operation. Shortened measuring intervals enable the rapid and reliable display of even the smallest deviations. This on-line monitoring process provides the certainty about the quality of your compressed air as an important element of your process safety at all times and at all quality-critical system points. The measurement data can be utilised for documenting the compressed air quality and for identifying contamination sources.

Function of oil vapour measuring

In the METPOINT®️ OCV compact system, a PID sensor works according to the principle of photo-ionization using a UV lamp. To increase the precision and to compensate for the smallest fluctuations, the determined values are temperature and pressure compensated. This fulfills the requirements of ISO 8573. As a continuous self-control of the measuring system, a reference gas generated by means of an integrated catalytic converter is used. In the periodic change between measuring air and reference air, the function of the PID measuring cell is continuously controlled and adjusted.

Internal reference gas generation by means of a purifier

Integrated reference gas generation

The METPOINT OCV compact has integrated reference gas treatment by means of a patented catalytic converter. The compressed air is hereby passed on to a heated catalytic converter surface and the hydrocarbons are decomposed catalytically to water (H₂O) and carbon dioxide (CO₂). This reference gas is then continuously routed in alternation with the normal compressed air sample into the measuring chamber and the oil content is measured with the photo-ionisation detector (PID). The measuring chamber is both regularly “cleaned” by this reference gas generation and the measuring system is inspected for its zero point. This “self-monitoring” provides you with the assurance that the system is working accurately in the long term.

Technical Data METPOINT®️ OCV compact

METPOINT

METPOINT OCV compact

Medium

Compressed air free of aggressive, corrosive, caustic, toxic, flammable and combustion supporting materials or substances.

The use of a compressed air preparation adapted to the measurement task is necessary.

Measured value

Residual oil content in mg of oil/normal m³, relative to 1.0 bar, +20°C, 0% relative humidity, according to ISO 8573-1

Detectable substances

Poly-alpha-olefines, aromatic and aliphatic hydrocarbons, functional hydrocarbons

Compressed air free of aggressive, corrosive, caustic, toxic, flammable and oxidizing substances

Applications

Downstream of activated carbon filter and activated-carbon adsorber,

downstream of BEKOKAT® (catalytic converter),

downstream of oil-free compressing compressor,

each with pre-switched filtration and drying

Ambient temperature, minimum/maximum

+5°C ... +45°C, rel. humidity ≤ 75%, non-condensing

Storage temperature

+5 °C ... +50 °C

Ambient pressure

800 ... 1200 mbar [a]

Climatic resistance

max. +10 °Ctd

Compressed air temperature, minimum/maximum

+5 °C ... +50 °C

Operating pressure

3 … 16 bar(g), optional pressure reducer which can be pre-switched for up to 300 bar(g)

Settings for operating pressure

By means of integrated pressure reducer with display

Measuring gas humidity

≤ 40 % relative humidity, max. pressure dew point +10 °C, non-condensing humidity

Compressed air connection

G 1/8” internal thread according to ISO 228-1

Measurement values

mg/standard m³, pressure and temperature compensated

Measuring range

≤ 0,01 … 2,50 mg/m³

Measured value display

a new measured value every 4 seconds

Calibrated measuring range

≤ 0.01 … 1.25 mg/m³ residual oil content, according to ISO 8573-1

Detection limit (residual oil)

0,001 mg/m³

Measuring range and accuracy

≤ 0,01 … 0,5 mg/m³ ± 0,003

≥ 0,5 … 1,0 mg/m³ ± 0,10

≥ 1,0 … 2,5 mg/m³ ± 0,10

Measuring gas flow rate

approx. 1.20 standard litres / minute relative to 1.0 bar(a) and +20 °C, in depressurised state

Display for adhering to an ISO

residual oil vapour class

As LED (red/green)

Reference gas generation

Integrated catalytic converter

Voltage supply

100 ... 240 VAC / 1 Ph. / PE / 50 ... 60 Hz / ± 10 %

Degree of protection

IP54 / DIN EN 60529

Interfaces

4 … 20 mA analogue output, 2-conductor system,

RS-485, MODBUS RTU for the transmission of measured values

1 alarm contact, normally open contact

Dimensions

410 x 440 x 163 mm (W x H x D)

Weight

approx. 16.3 kg

Downloads

Technical information of METPOINT®️ OCV compact, PDF( Size: 800 KB )

Technical Data of METPOINT®️ OCV compact, PDF( Size: 133 KB )

Catalog METPOINT®️ OCV compact , PDF( Size: 1.7 MB )

METPOINT®️ OCV compact measuring section

From

Net €457.00

€543.83*

METPOINT®️ OCV compact measuring section - oil vapour measuring sectio

Meaningful results by using the right measurements

Measurement value for mean value formation

The compressed air composition hardly ever alters, apart from during malfunctions continuous oil vapour monitoring should be designed in such a way that gradual deterioration or sudden failure of a cleaning stage are indicated reliably. Under specific operating conditions, peak values that occur only briefly are recorded and displayed, although they are not always due to a fault in the compressed air treatment or a defect in the measuring device. If these peaks only occur at very short time intervals, or they relate to individual measured values, they are due to other factors of influence rather than hydrocarbons in the sense of the oil definition. For this reason, the METPOINT ® OCV compact provides a measurement recording with floating mean value formation over defined times in order to eliminate individual measured value outliers automatically.

Sampling (measuring section)

If the oil classes defined in ISO 8573 are considered, the detection of hydrocarbons of Class 1 i.e. smaller than 0.010 mg/ m³ = 10 μg/m³ can be designated as trace analysis. The sampling type and method is of particular importance in this range. The sample should be taken at a point where it can be ensured that a representative and usable mixture of all components of the compressed air is present. In the case of a homogeneous distribution over the pipe cross-section, the gas sample can be taken at a fixed point approximately at the centre of the pipe cross-section.

Technical Data METPOINT®️ OCV compact measuring section

Material

Stainless steel free of oil and grease

Connection for sampling probe E

3/8" Internal thread oil-free

Whitworth tapered pipe thread

DIN 2999

measuring section

DN 20 3/4"

DN 25 1"

DN 32 1 1/4"

DN 40 1 1/2"

DN 50 2"

DN 65 2 1/2"

DN 80 3"

Typ

MS-2016

MS-2516

MS-3216

MS-4016

MS-5016

MS-6510

MS-8010

PN (bar [ü])

16

16

16

16

16

10

10

A (mm)

430

480

550

600

905

1105

1155

B (mm)

120

120

130

180

190

260

320

C (mm)

475

530

610

670

980

1220

1270

R

R3/4"

R1"

R1 1/4"

R1 1/2"

R2"

R2 1/2"

R3"

D1 (ø mm)

26,9 x 2,6

33,7 x 3,6

42,4 x 3,6

48,3 x 3,6

60,3 x 3,6

76,1 x 3,6

88,9 x 4,0

Bestell-Nr.

4013229

4013230

4013233

4013234

4013235

4013265

4013266

Preis (€)

457

509

574

661

877

1295

1689

Downloads

Technical information of METPOINT®️ OCV compact, PDF( Size: 800 KB )

Technical Data of METPOINT®️ OCV compact, PDF( Size: 133 KB )

Catalog METPOINT®️ OCV compact , PDF( Size: 1.7 MB )

METPOINT®️ OCV compact accessories

Net €578.00

€687.82*

METPOINT®️ OCV compact accessories - oil vapour measuring accessorie

Ball valve oil- and grease-free with Stainless steel tubing incl. screw joints

4014394 , Ball valve oil- and grease-free

4042085 , METPOINT®️ OCV: accessories for the horizontal installation:

Stainless steel pipe 6 x 1 mm

›› Length max. 1000 mm

For 4014085:

›› incl. 2 piece of connection fitting G 3/8" external thread

For 4042085:

›› incl. 1 piece of connection fitting G 3/8" external thread

›› incl. 1 piece of connection fitting G 1/8" external thread

Downloads

Technical information of METPOINT®️ OCV compact, PDF( Size: 800 KB )

Technical Data of METPOINT®️ OCV compact, PDF( Size: 133 KB )

Catalog METPOINT®️ OCV compact , PDF( Size: 1.7 MB )