Product information "BEKOMAT® 16 CO, BEKO condensate drain "

Condensate drainage without loss of compressed air

If a float arrester leaks, high costs arise as a result of leaks. Time-controlled solenoid valves also cause compressed air losses. During the valve opening expensive compressed air escapes unused into the environment. In contrast, a condensate drain with electronic level control guarantees draining without compressed air, ie energy loss. This not only saves energy and costs, but also CO 2 emissions. This is a fantastic condensate drainage without loss of compressed air.Technical data of BEKOMAT® 16 CO

| BEKOMAT® | BEKOMAT® 16 CO |

| Max. compressor performance [m³/min] | 1400 |

| Max. dryer performance [m³/min] | 2800 |

| Max. filter performance [m3/min] | |

| Voltage | 230VAC / 50-60Hz |

| Operating pressure [bar] | 0.8 - 16 |

| Temperature [°C] | +1 bis + 60 |

| Condensate feed | 2 x G 3/4 | 1 x G 1 |

| Condensate drain | DN 10-13 bzw. G 1/2i |

| Dimenstions B x T x H [mm] | 260 x 280 x 280 |

| Weight [kg] | ca. 6,1 |

Further safety advice:

• For installation and operation, the national regulations and safety codes in force must also be adhered to.

• Do not use the BEKOMAT® 16 in hazardous areas.

• Regarding the inlet screw joints, excessive tightening forces must be avoided. This applies in particular to conical screw joints.

• The BEKOMAT® 16 will only function when voltage is applied.

• Do not use the test button for permanent drainage!

• Only use genuine spare parts! This is imperative to ensure perfect functioning.

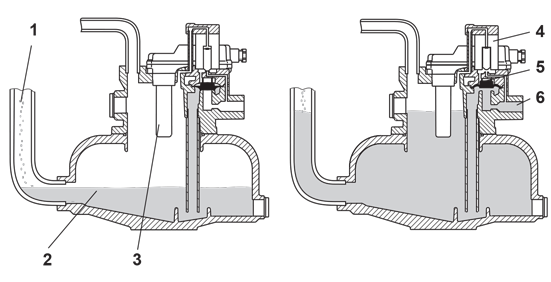

Function Of BEKOMAT® 16 CO

The condensate flows through the feed line (1) into the BEKOMAT® unit and accumulates in the container (2). A capacitive sensor (3) continuously registers the liquid level and passes a signal to the electronic control as soon as the container is filled. The pilot valve (4) is then activated and the diaphragm (5) opens the outlet line (6) for discharging the condensate. When the BEKOMAT® unit has been emptied, the outlet line is closed again quickly and tightly without wasting compressed air.

1- Ready for operation

Voltage is being applied

2- Discharge procedure

Outlet line is open

3- Malfunction

Alarm mode is activated

4- Test

Manual drainage / alarm

When the microcontroller registers a malfunction, the device will automatically change to the alarm mode. The switching sequence of the valve (see illustration) continues until the fault is cleared (automatically or through maintenance). The red LED flashes as long as the device is in the alarm mode.

Malfunctioning could be caused by, e.g.:

• Mistakes during installation

• Dropping below the necessary minimum pressure

• Excessive condensate quantities (overloading)

• Blocked / shut off outlet line

• Extreme amount of dirt particles

• Frozen piping If the fault is not cleared within the first minute, a fault signal is triggered (see illustration) which can be picked off as a potential-free signal via the alarm relay.

Malfunctioning could be caused by, e.g.:

• Mistakes during installation

• Dropping below the necessary minimum pressure

• Excessive condensate quantities (overloading)

• Blocked / shut off outlet line

• Extreme amount of dirt particles

• Frozen piping If the fault is not cleared within the first minute, a fault signal is triggered (see illustration) which can be picked off as a potential-free signal via the alarm relay.

Downloads

Technical Data BEKOMAT® 16 CO , PDF( Size: 1.2 MB )

Catalog BEKOMAT® 16 CO , PDF( Size: 430 KB )

Login