Product number:

2000164

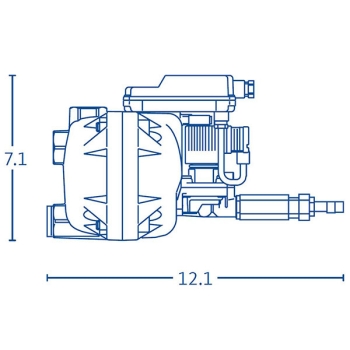

Product information "BEKOMAT® 14, 14CO, 14CO PN25, BEKO condensate drain"

BEKO condensate drain BEKOMAT® 14, 14CO, 14CO PN25

Proper use

• The BEKOMAT® is an electronically level-controlled condensate drain for compressed-air plants.

• It is employed within the permissible operating parameters (see "Technical data").

• The BEKOMAT® is able to drain condensate under operating pressure from the plant components virtually without compressed-air losses.

• For its function, the BEKOMAT® 14 requires an operating voltage and an operating pressure (see "Technical data").

• As far as the employment in plants with increased demands on the compressed-air quality is concerned (food industry, medical technology, laboratory equipment, special processes etc.), the operator must decide on measures for the monitoring of the compressed-air quality. These have an effect on the safety of the subsequent processes and may prevent damage to persons and plants.

• It is the task of the operator to ensure that the indicated conditions are met during the entire operating time.

• For the employment in CO2 plants, a BEKOMAT® with a CO specification (BEKOMAT® ... CO) must be used.

• The BEKOMAT® and the condensate supply line need to be protected against frost, as otherwise the function cannot be guaranteed. BEKO TECHNOLOGIES GMBH also offers suitable products for this purpose.

Downloads

Technical Data BEKOMAT® 14, 14CO, 14CO PN25 , PDF( Size: 1.5 MB )

Catalog BEKOMAT® 14, 14CO, 14CO PN25 , PDF( Size: 430 KB )

Cost-effective and reliable: BEKOMAT ® standard units

The BEKOMAT® range provides the 12, 13, 14 and BEKOMAT 16 standard units for virtually every application, which are not just the correct solution, rather more also the most suitable low-energy solution. The integrated capacitive sensor for volume-controlled condensate discharge helps save energy and enhances efficiency – which is what you would expect from BEKOMAT.Unnecessary costs and damage in the compressed air generation can only be efficiently prevented with volume-controlled condensate discharge. For this reason, BEKOMAT condensate drain therefore functions with a capacitive sensor. The intelligent electronics prevent compressed air losses and minimise energy consumption. Due to this the electronically regulated condensate discharge, the drain often amortises itself within half a year compared to devices with time-controlled drain valves.

Technical Data BEKOMAT® 14, 14CO, 14CO PN25

| BEKOMAT®

|

14 | 14 CO | 14 CO PN25 |

| Max. compressor capacity | 150 m3/min | ||

| Max. refrigeration dryer performance | 300 m3/min | ||

| Max. filter performance | 1500 m3/min | ||

| Min./max. operating pressure | 0,8 ... 16 bar (g) | 1.2 ... 25 bar (gauge) | |

| Housing | Aluminium | Aluminium, hard-coated | |

| Ambient temperature | +1 °C … +60 °C | ||

|

Weight (empty)

|

2.9 kg | 3.1 kg | |

| Condensate inlet | 3 x G¾ (inside) [optional: NPT thread] | ||

| Condensate discharge | 1 x G½ (outside); hose connector, hose Ø = 13 mm (inside) | 1 x G⅜ (inside); hose connector, hose Ø = 13 mm (inside) | |

| Operating voltage | 230 / 200 / 115 / 100 / 24 VAC ± 10%, 50 ... 60 Hz / 24 VDC ± 10% | ||

| Power consumption | P < 8,0 VA (W) | ||

| Protection class | IP 65 | ||

| Wire cross-section (mains connection) | recommended 3 x 0.75 … 1.5 mm2 (AWG 16 ... 18) | ||

| Protection | recommended for AC: 1 A slow / mandatory for DC: 1 A slow | ||

| Contact load | max. AC 250 V, DC 30 V / 1A; min. DC 5V / 10 mA | ||

| Condensate | oil-contaminated condensate | oil-contaminated condensate; oil-free, potentially aggressive condensate | |

Proper use

• The BEKOMAT® is an electronically level-controlled condensate drain for compressed-air plants.

• It is employed within the permissible operating parameters (see "Technical data").

• The BEKOMAT® is able to drain condensate under operating pressure from the plant components virtually without compressed-air losses.

• For its function, the BEKOMAT® 14 requires an operating voltage and an operating pressure (see "Technical data").

• As far as the employment in plants with increased demands on the compressed-air quality is concerned (food industry, medical technology, laboratory equipment, special processes etc.), the operator must decide on measures for the monitoring of the compressed-air quality. These have an effect on the safety of the subsequent processes and may prevent damage to persons and plants.

• It is the task of the operator to ensure that the indicated conditions are met during the entire operating time.

• For the employment in CO2 plants, a BEKOMAT® with a CO specification (BEKOMAT® ... CO) must be used.

• The BEKOMAT® and the condensate supply line need to be protected against frost, as otherwise the function cannot be guaranteed. BEKO TECHNOLOGIES GMBH also offers suitable products for this purpose.

Downloads

Technical Data BEKOMAT® 14, 14CO, 14CO PN25 , PDF( Size: 1.5 MB )

Catalog BEKOMAT® 14, 14CO, 14CO PN25 , PDF( Size: 430 KB )

Login