€238.00

Net€283.22*

Available, delivery time: Approximately 2-3 weeks

Product number:

4008728

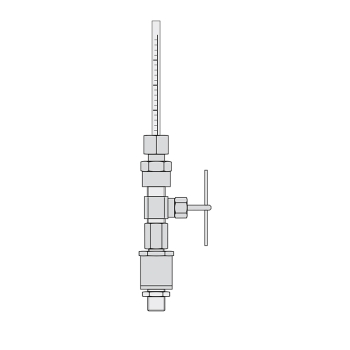

Product information "Oil Check Indicator, completely BERG"

Oil Check Indicator, completely BERG

When the needle valve of the oil indicator is open, less than 2 SCIM/PSIG (0.08 ml/s/kPa) will flow through the calibrated plastic tube. Any oil present in the air will then carry a red oil soluble dye up the tube, coloring a white material in the tube. The rate of color travel will be proportional to the amount of oil present. The parts per million (PPM) valve of oil entrained in the sir can be determined using the conversion chart included with the instrument. After use, the needle valve should be closed and left in the line and the cartridge removed. At the time of the next test, a replacement cartridge will need to be installed on the needle valve fitting.

In order for the oil indicator to properly measure a given oil entrainment, sufficient exposure time is required. The length of exposure time is inversely proportional to the pressure at the point of installation. When using the indicator to check for oil carryover from the compressor, it should be installed at the discharge of the tank. When using the indicator to measure oil entrainment in the air supply system, it should be installed between the oil filter and the pressure reducing valve (PRV). At this point, dry high pressure air will be present, resulting in the best accuracy and fastest indication.

Downloads

Oil Check Indicator Instructions for installation and operation , PDF( Size: 332 KB )

The oil check indicator is a calibrated measuring instrument used to detect aerosol-mist levels of oil entrainment that may be present in compressed air systems. Sensitivity of the indicator is limited only by the total number of hours it is allowed to remain on the air supply system. The indicator is sensitive enough to measure a concentration of oil entrainment as low as 0.01 PPM (0.012mg/m3) in a compressed air system. It can be used in systems with line pressures between 10 and 125 PSIG (70 and 875 kPa).

Application Oil check indicator

Oil entrainment in the control air supply to the pressure reducing valve may eventually have an adverse effect on the control system performance. Since some oil entrainment is inherent to lubricated compressor installations must include factory approved oil filters to be reliably acceptable. The indicator can be used in two ways. Either it can be used to check for oil carryover from the compressor or it can be used to check out any filtered air supply source before connecting it to the system and also every few months after the system becomes operative. Once the needle valve of the oil indicator has been opened, one continuous uninterrupted exposure is recommended foe greatest accuracy.

Operation Oil check indicator

When the needle valve of the oil indicator is open, less than 2 SCIM/PSIG (0.08 ml/s/kPa) will flow through the calibrated plastic tube. Any oil present in the air will then carry a red oil soluble dye up the tube, coloring a white material in the tube. The rate of color travel will be proportional to the amount of oil present. The parts per million (PPM) valve of oil entrained in the sir can be determined using the conversion chart included with the instrument. After use, the needle valve should be closed and left in the line and the cartridge removed. At the time of the next test, a replacement cartridge will need to be installed on the needle valve fitting.

Installation Oil check indicator

In order for the oil indicator to properly measure a given oil entrainment, sufficient exposure time is required. The length of exposure time is inversely proportional to the pressure at the point of installation. When using the indicator to check for oil carryover from the compressor, it should be installed at the discharge of the tank. When using the indicator to measure oil entrainment in the air supply system, it should be installed between the oil filter and the pressure reducing valve (PRV). At this point, dry high pressure air will be present, resulting in the best accuracy and fastest indication.

Technical Data of Oil Check Indicator

| Oil Check Indicator BERG | |

| Air consumption | 1.9 SCIM/PSIG (0.07 mL/s/kPa) |

| Max. temperature rating [°C] | 49 |

| Pressure range | 10 - 125 PSIG |

| Oil concentration Range [mg/m3] | 0 - 30 |

| Accessory | Oil indicator replacement cartridge |

| Mass [kg] | 0.200 |

Downloads

Oil Check Indicator Instructions for installation and operation , PDF( Size: 332 KB )

Login