Product number:

4011570

Product information "OWAMAT® 11 , 4.9m3/min Oil water separator "

Oil water separator OWAMAT® 11 - QWIK-PURE CS200, 4.9m3/min

Safe and efficient condensate separation: OWAMAT®

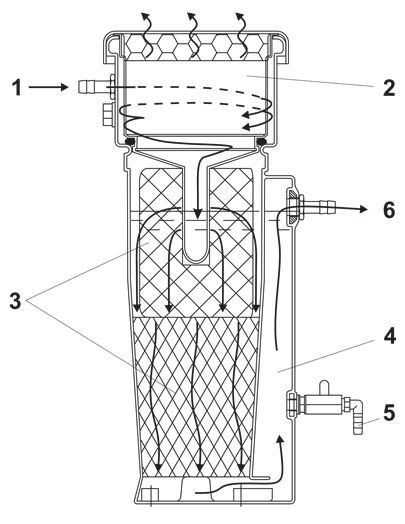

OWAMAT has been a tried and tested oil-water separation system for dispersed condensates for decades. It has been awarded a building regulation´s approval for the versions with and without free oil separation, for synthetic or mineral oils as well as for processing condensate generated by piston- and screw compressors, therefore not requiring any legislation for water protection approval.Function of oil water separator OWAMAT® 10,11

|

The oil-contaminated condensate can be fed under pressure to the OWAMAT® unit (1). The pressure is reduced in the pressure relief chamber (2). The condensate flows steadily into the subjacent filter stage without turbulence and runs through the two-stage OEKOSORB® replacement filter. The OEKOSORB® replacement filter (3) comprises a prefilter and a main filter for binding any residual oil constituents. The water flows out of the OWAMAT® oil-water separator through the water outlet (6) and can be discharged directly into the sewer system. A sampling valve (5) is provided so that the wastewater quality can be checked at any time. 1 Condensate inlet 2 Pressure relief chamber 3 Prefilter/main filter 4 Riser 5 Sampling valve 6 Water outlet |

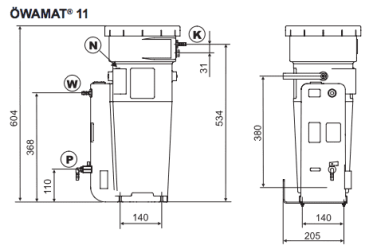

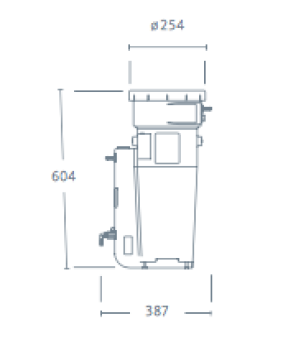

Technical Data of Oil water separator OWAMAT® 11

| Oil water separator OWAMAT® | OWAMAT® 11 |

| max.compressor performance: | 4.9 m3/min |

| Container volume: | 18.6 l |

| Capacity: | 11.7 l |

| Pre lter: | 4.7 l |

| Main lter: | 4.8 l |

| Condensate inlet (hose size): | 2 x G1⁄2 inside (Ø inside = 10 mm) |

| Water (hose size): | 1 x G1⁄2 inside (Ø inside = 10 mm) |

| Weight (empty): | 5.75 kg |

| Min./max. temperature | +5 ... +60 °C |

| Max. operating pressure at inlet | 16 bar |

Downloads

Technical Data of Oil water separator OWAMAT® 10,11 , PDF( Size: 747 KB )

Catalog Oil water separator , PDF( Size: 309 KB )

Login